Fitting a dual stress model to ALT data

Before reading this section it is recommended that readers are familiar with the concepts of fitting probability distributions, probability plotting, and have an understanding of what accelerated life testing (ALT) involves.

The module reliability.ALT_fitters contains 24 ALT models; 12 of these models are for single stress and 12 are for dual stress. This section details the dual stress models, though the process for fitting single stress models is similar. The decision to use a single stress or dual stress model depends entirely on your data. If your data has two stresses that are being changed then you will use a dual stress model.

The following dual stress models are available within ALT_fitters:

Fit_Weibull_Dual_Exponential

Fit_Weibull_Power_Exponential

Fit_Weibull_Dual_Power

Fit_Lognormal_Dual_Exponential

Fit_Lognormal_Power_Exponential

Fit_Lognormal_Dual_Power

Fit_Normal_Dual_Exponential

Fit_Normal_Power_Exponential

Fit_Normal_Dual_Power

Fit_Exponential_Dual_Exponential

Fit_Exponential_Power_Exponential

Fit_Exponential_Dual_Power

API Reference

For inputs and outputs see the API reference.

Example 1

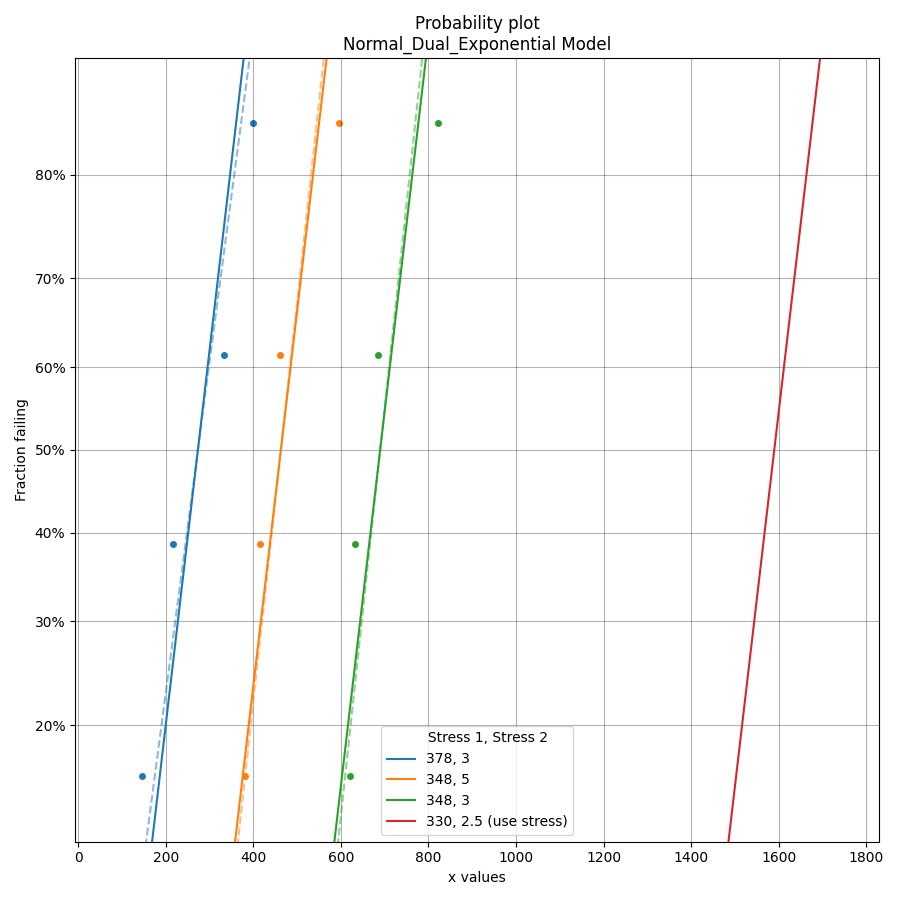

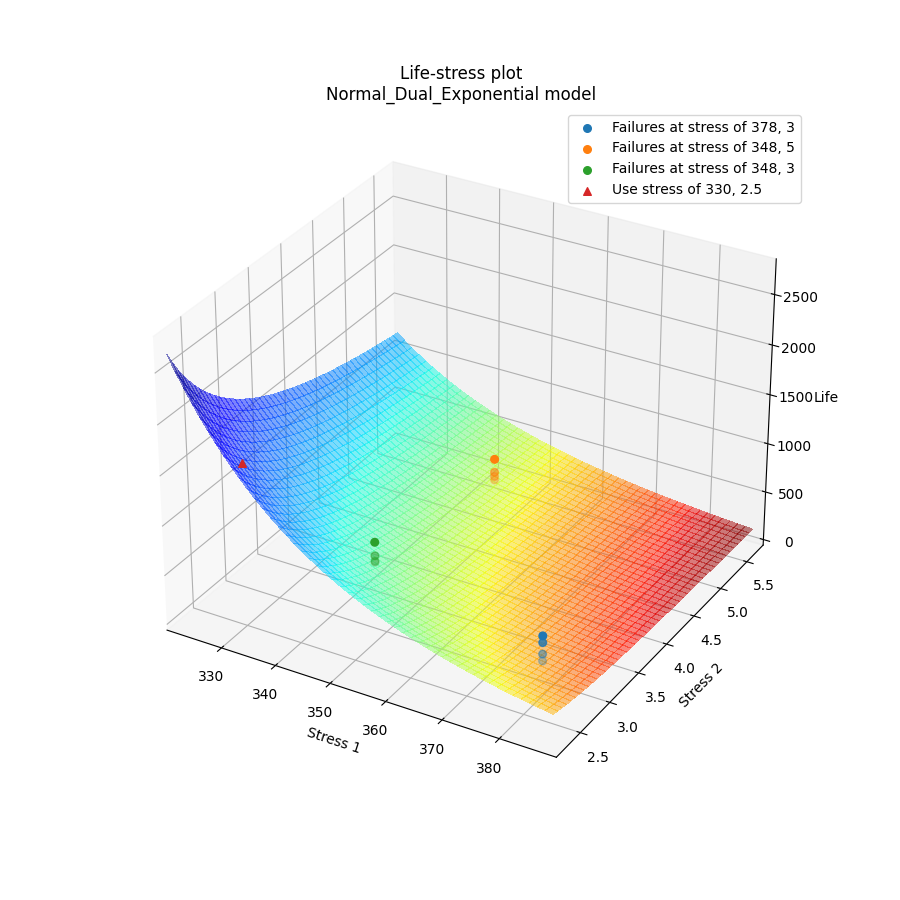

In the following example, we will fit the Normal-Dual-Exponential model to an ALT dataset obtained from a temperature-voltage dual stress test. This dataset can be found in reliability.Datasets. We want to know the mean life at the use level stress of 330 Kelvin, 2.5 Volts so the parameter use_level_stress is specified. All other values are left as defaults and the results and plot are shown.

from reliability.Datasets import ALT_temperature_voltage

from reliability.ALT_fitters import Fit_Normal_Dual_Exponential

import matplotlib.pyplot as plt

data = ALT_temperature_voltage()

Fit_Normal_Dual_Exponential(failures=data.failures, failure_stress_1=data.failure_stress_temp, failure_stress_2=data.failure_stress_voltage,use_level_stress=[330,2.5])

plt.show()

'''

Results from Fit_Normal_Dual_Exponential (95% CI):

Analysis method: Maximum Likelihood Estimation (MLE)

Optimizer: TNC

Failures / Right censored: 12/0 (0% right censored)

Parameter Point Estimate Standard Error Lower CI Upper CI

a 4056.06 752.936 2580.33 5531.78

b 2.98949 0.851782 1.32002 4.65895

c 0.00220837 0.00488704 2.88663e-05 0.168947

sigma 87.3192 17.824 58.5274 130.275

stress original mu original sigma new mu common sigma sigma change acceleration factor

378, 3 273.5 98.7256 273.5 87.3192 -11.55% 5.81285

348, 5 463 81.8474 463.001 87.3192 +6.69% 3.43371

348, 3 689.75 80.176 689.749 87.3192 +8.91% 2.30492

Goodness of fit Value

Log-likelihood -70.6621

AICc 155.039

BIC 151.264

At the use level stress of 330, 2.5, the mean life is 1589.81428

'''

In the results above we see 3 tables of results; the fitted parameters (along with their confidence bounds) dataframe, the change of parameters dataframe, and the goodness of fit dataframe. For the change of parameters dataframe the “original mu” and “original sigma” are the fitted values for the Normal_2P distribution that is fitted to the data at each stress (shown on the probability plot by the dashed lines). The “new mu” and “new sigma” are from the Normal_Dual_Exponential model. The sigma change is extremely important as it allows us to identify whether the fitted ALT model is appropriate at each stress level. A sigma change of over 50% will trigger a warning to be printed informing the user that the failure mode may be changing across different stresses, or that the model is inappropriate for the data. The acceleration factor column will only be returned if the use level stress is provided since acceleration factor is a comparison of the life at the higher stress vs the use stress.

Example 2

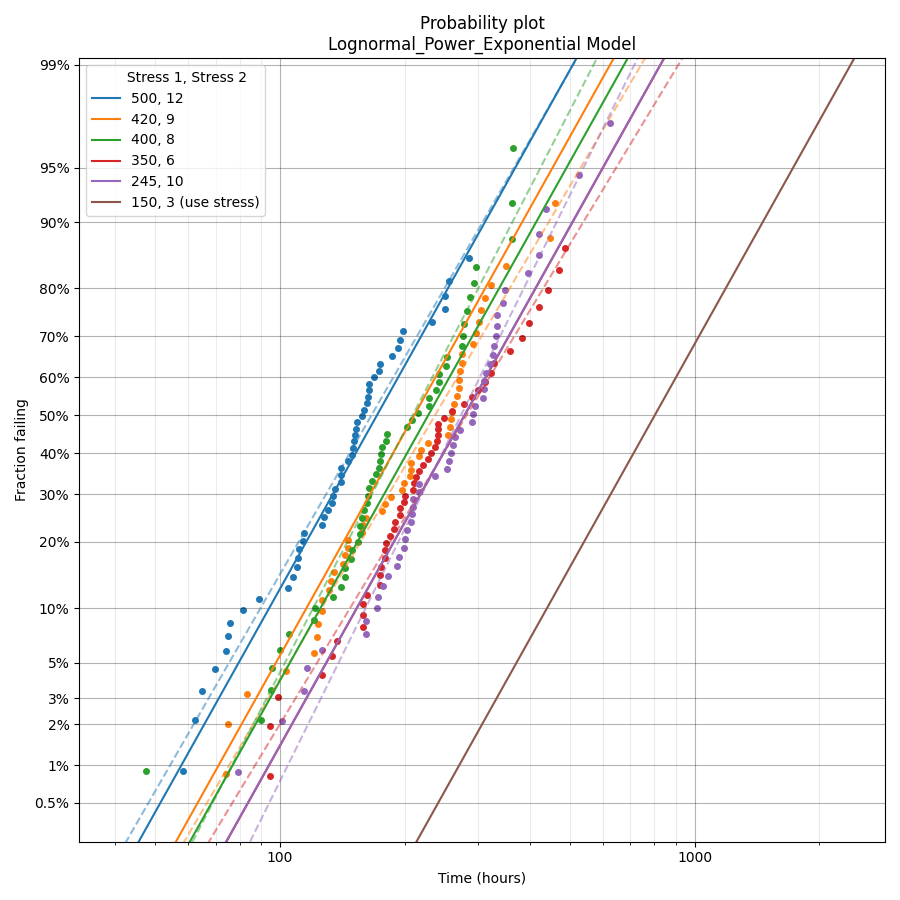

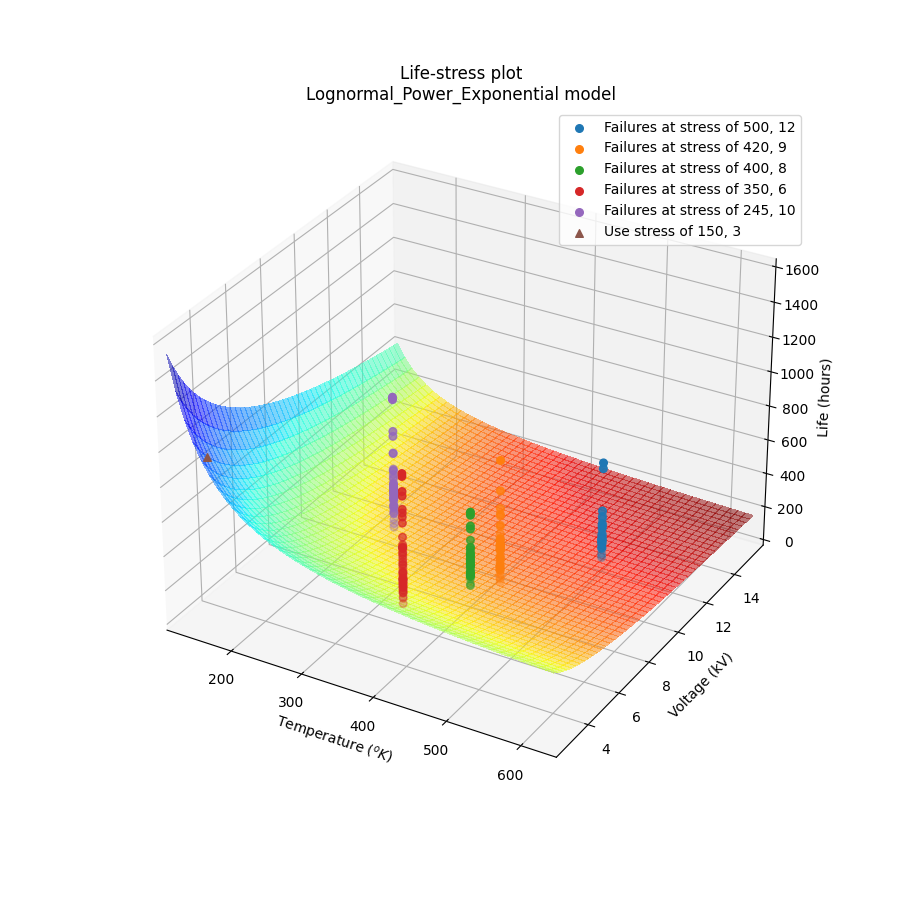

In this second example we will fit the Lognormal_Power_Exponential model. Instead of using an existing dataset we will create our own data using the function make_ALT_data. The results show that the fitted parameters agree well with the parameters we used to generate the data, as does the mean life at the use stress. This accuracy improves with more data.

Two of the outputs returned are the axes handles for the probability plot and the life-stress plot. These handles can be used to set certain values. In the example below we see the axes labels being set to custom values after the plots have been generated but before the plots have been displayed.

from reliability.Other_functions import make_ALT_data

from reliability.ALT_fitters import Fit_Lognormal_Power_Exponential

import matplotlib.pyplot as plt

use_level_stress = [150,3]

ALT_data = make_ALT_data(distribution='Lognormal',life_stress_model='Power_Exponential',a=200,c=400,n=-0.5,sigma=0.5,stress_1=[500,400,350,420,245],stress_2=[12,8,6,9,10],number_of_samples=100,fraction_censored=0.5,seed=1,use_level_stress=use_level_stress)

model = Fit_Lognormal_Power_Exponential(failures=ALT_data.failures, failure_stress_1=ALT_data.failure_stresses_1, failure_stress_2=ALT_data.failure_stresses_2, right_censored=ALT_data.right_censored, right_censored_stress_1=ALT_data.right_censored_stresses_1,right_censored_stress_2=ALT_data.right_censored_stresses_2, use_level_stress=use_level_stress)

# this will change the xlabel on the probability plot

model.probability_plot.set_xlabel('Time (hours)')

# this will change the axes labels on the life-stress plot

model.life_stress_plot.set_xlabel('Temperature $(^oK)$')

model.life_stress_plot.set_ylabel('Voltage (kV)')

model.life_stress_plot.set_zlabel('Life (hours)')

print('The mean life at use stress of the true model is:',ALT_data.mean_life_at_use_stress)

plt.show()

'''

Results from Fit_Lognormal_Power_Exponential (95% CI):

Analysis method: Maximum Likelihood Estimation (MLE)

Optimizer: TNC

Failures / Right censored: 250/250 (50% right censored)

Parameter Point Estimate Standard Error Lower CI Upper CI

a 192.105 39.4889 114.708 269.502

c 451.448 134.274 252.02 808.687

n -0.49196 0.12119 -0.729488 -0.254433

sigma 0.491052 0.0212103 0.451191 0.534433

stress original mu original sigma new mu common sigma sigma change acceleration factor

500, 12 5.29465 0.496646 5.2742 0.491052 -1.13% 4.84765

420, 9 5.54536 0.525041 5.48891 0.491052 -6.47% 3.91096

400, 8 5.42988 0.392672 5.56972 0.491052 +25.05% 3.60733

350, 6 5.84254 0.550746 5.77986 0.491052 -10.84% 2.92364

245, 10 5.75338 0.457948 5.76378 0.491052 +7.23% 2.97102

Goodness of fit Value

Log-likelihood -1596.29

AICc 3200.66

BIC 3217.44

At the use level stress of 150, 3, the mean life is 1067.69246

The mean life at use stress of the true model is: 992.7627728988726

'''

Note

In the dual-stress life stress plots, there is a known visibility issue inherent in matplotlib where the 3D surface plot and the scatter plots are drawn in layers (relative to the observer). This results in the scatter plot always appearing in front of the 3D surface, even when some of the points should actually be occluded by the surface. The layering was chosen to show the scatter plot above the 3D surface plot as this provides better visibility than the alternative.

References:

Probabilistic Physics of Failure Approach to Reliability (2017), by M. Modarres, M. Amiri, and C. Jackson. pp. 136-168

Accelerated Life Testing Data Analysis Reference - ReliaWiki, Reliawiki.com, 2019. [Online].