Stress-strain and strain-life

In the strain-life method of fatigue analysis, the elastic and plastic deformation of the material is used to determine how many cycles the material will last before failure. In this context, failure is defined as the formation of a small crack (typically 1mm) so the geometry of the material does not need to be considered provided the material peoperties have been accurately measured using a stress-strain test. This section of the documentation describes three functions which are useful in strain-life analysis. The first of these is useful to fit the stress-strain and strain-life models to available data, thereby providing the material properties. The second function is a diagram of the relationship between stress and strain during cyclic fatigue which shows the hysteresis loop and finds the min and max stress and strain. The third function produces the strain-life diagram and the equations for this diagram are used for calculating the number of cycles to failure. Further detail is available below for each of the respective functions.

The equations used for stress-strain and strain life are:

\(\text{Ramberg-Osgood equation:} \hspace{41mm} \varepsilon_{tot} = \underbrace{\frac{\sigma}{E}}_{\text{elastic}} + \underbrace{\left(\frac{\sigma}{K}\right)^{\frac{1}{n}}}_{\text{plastic}}\)

\(\text{Hysteresis curve equation:} \hspace{43mm} \Delta\varepsilon = \underbrace{\frac{\Delta\sigma}{E}}_{\text{elastic}} + \underbrace{2\left(\frac{\Delta\sigma}{2K}\right)^{\frac{1}{n}}}_{\text{plastic}}\)

\(\text{Coffin-Manson equation:} \hspace{46mm} \varepsilon_{tot} = \underbrace{\frac{\sigma_f}{E}\left(2N_f\right)^b}_{\text{elastic}} + \underbrace{\varepsilon_f\left(2N_f\right)^c}_{\text{plastic}}\)

\(\text{Morrow Mean Stress Correction:} \hspace{30mm} \varepsilon_{tot} = \underbrace{\frac{\sigma_f-\sigma_m}{E}\left(2N_f\right)^b}_{\text{elastic}} + \underbrace{\varepsilon_f\left(2N_f\right)^c}_{\text{plastic}}\)

\(\text{Modified Morrow Mean Stress Correction:} \hspace{10mm} \varepsilon_{tot} = \underbrace{\frac{\sigma_f-\sigma_m}{E}\left(2N_f\right)^b}_{\text{elastic}} + \underbrace{\varepsilon_f\left(\frac{\sigma_f-\sigma_m}{\sigma_f}\right)^{\frac{c}{b}}\left(2N_f\right)^c}_{\text{plastic}}\)

\(\text{Smith-Watson-Topper Mean Stress Correction:} \hspace{2mm} \varepsilon_{tot} = \underbrace{\frac{\sigma_f^2}{\sigma_{max}E}\left(2N_f\right)^{2b}}_{\text{elastic}} + \underbrace{\frac{\sigma_f\varepsilon_f}{\sigma_{max}}\left(2N_f\right)^{b+c}}_{\text{plastic}}\)

Stress-Strain and Strain-Life parameter estimation

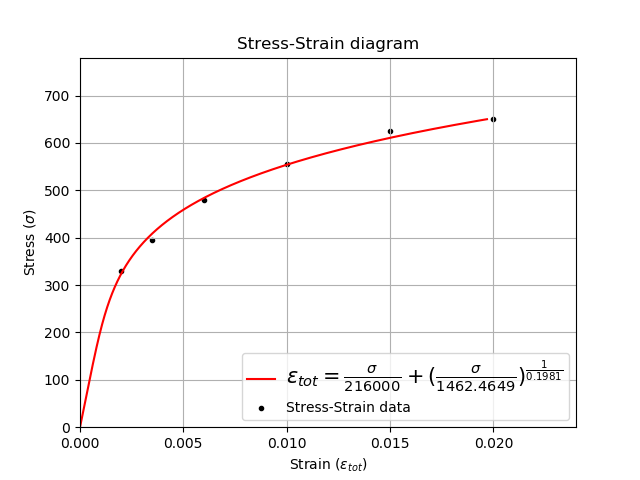

The function stress_strain_life_parameters_from_data will use stress and strain data to calculate the stress-strain parameters (K, n) from the Ramberg-Osgood relationship. If cycles is provided it will also produce the strain-life parameters (sigma_f, epsilon_f, b, c) from the Coffin-Manson equation. You cannot find the strain-life parameters without stress as we must use stress to find elastic strain. Note that if you already have the parameters K, n, sigma_f, epsilon_f, b, c, then you can use the functions ‘stress_strain_diagram’ or ‘strain_life_diagram’ as described below.

API Reference

For inputs and outputs see the API reference.

Example 1

In the example below, we provide data from a fatigue test including stress, strain, and cycles to failure. We must also provide the modulus of elasticity (E) for the material. All other options are left as default values. The plots shown below are provided and the results are printed to the console.

from reliability.PoF import stress_strain_life_parameters_from_data

import matplotlib.pyplot as plt

strain_data = [0.02, 0.015, 0.01, 0.006, 0.0035, 0.002]

stress_data = [650, 625, 555, 480, 395, 330]

cycles_data = [200, 350, 1100, 4600, 26000, 560000]

params = stress_strain_life_parameters_from_data(stress=stress_data, strain=strain_data,cycles=cycles_data, E=216000)

plt.show()

'''

Results from stress_strain_life_parameters_from_data:

K (cyclic strength coefficient): 1462.4649152172044

n (strain hardening exponent): 0.19810419512368083

sigma_f (fatigue strength coefficient): 1097.405402055844

epsilon_f (fatigue strain coefficient): 0.23664541556833998

b (elastic strain exponent): -0.08898339316495743

c (plastic strain exponent): -0.4501077996416115

'''

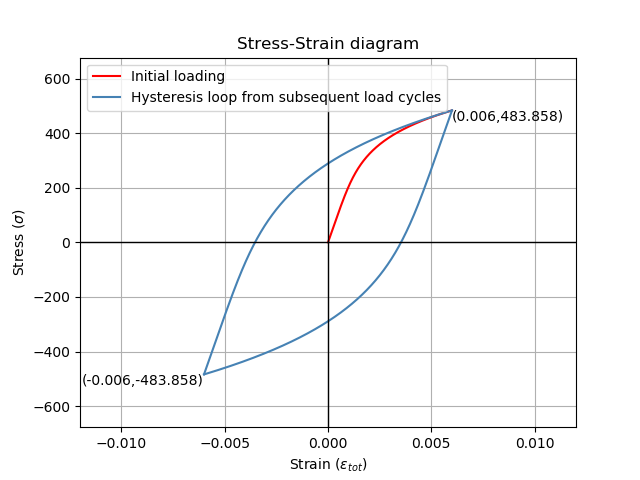

Stress-Strain diagram

The function stress_strain_diagram is used to visualize how the stress and strain vary with successive load cycles as described by the hysteresis curve equation. Due to residual tensile and compressive stresses, the stress and strain in the material does not unload in the same way that it loads. This results in a hysteresis loop being formed and this is the basis for crack propagation in the material leading to fatigue failure. The size of the hysteresis loop increases for higher strains. Fatigue tests are typically strain controlled; that is they are subjected to a specified amount of strain throughout the test, typically in a sinusoidal pattern. Fatigue tests may also be stress controlled, whereby the material is subjected to a specified amount of stress. This function accepts either input (max_stress or max_strain) and will find the corresponding stress or strain as required. If you do not specify min_stress or min_strain then it is assumed to be negative of the maximum value.

The cyclic loading sequence defaults to begin with tension, but can be changed using initial_load_direction=’compression’. If your test begins with compression it is important to specify this as the residual stresses in the material from the initial loading will affect the results for the first reversal. This difference is caused by the Bauschinger effect. Only the initial loading and the first two reversals are plotted. For most materials the shape of the hysteresis loop will change over many hundreds of cycles as a result of fatigue hardening (also known as work-hardening) or fatigue-softening. More on this process is available in the eFatigue training documents.

Note that if you do not have the parameters K, n, but you do have stress and strain data then you can use the function ‘stress_strain_life_parameters_from_data’. This will be shown in the first example below.

API Reference

For inputs and outputs see the API reference.

Example 2

In the example below, we are using the same data from the first example, but this time, we will store the calculated parameters in an object named ‘params’. Then we can specify the calculated parameters to the stress_strain_diagram function. The hysteresis loop generated is for a strain-controlled fatigue test where the strain goes from -0.006 to +0.006.

from reliability.PoF import stress_strain_life_parameters_from_data, stress_strain_diagram

import matplotlib.pyplot as plt

strain_data = [0.02, 0.015, 0.01, 0.006, 0.0035, 0.002]

stress_data = [650, 625, 555, 480, 395, 330]

cycles_data = [200, 350, 1100, 4600, 26000, 560000]

params = stress_strain_life_parameters_from_data(stress=stress_data, strain=strain_data, cycles=cycles_data, E=216000, show_plot=False, print_results=False)

stress_strain_diagram(E = 216000,n = params.n, K = params.K, max_strain=0.006)

plt.show()

'''

Results from stress_strain_diagram:

Max stress: 483.8581623940648

Min stress: -483.8581623940648

Max strain: 0.006

Min strain: -0.006

'''

Example 3

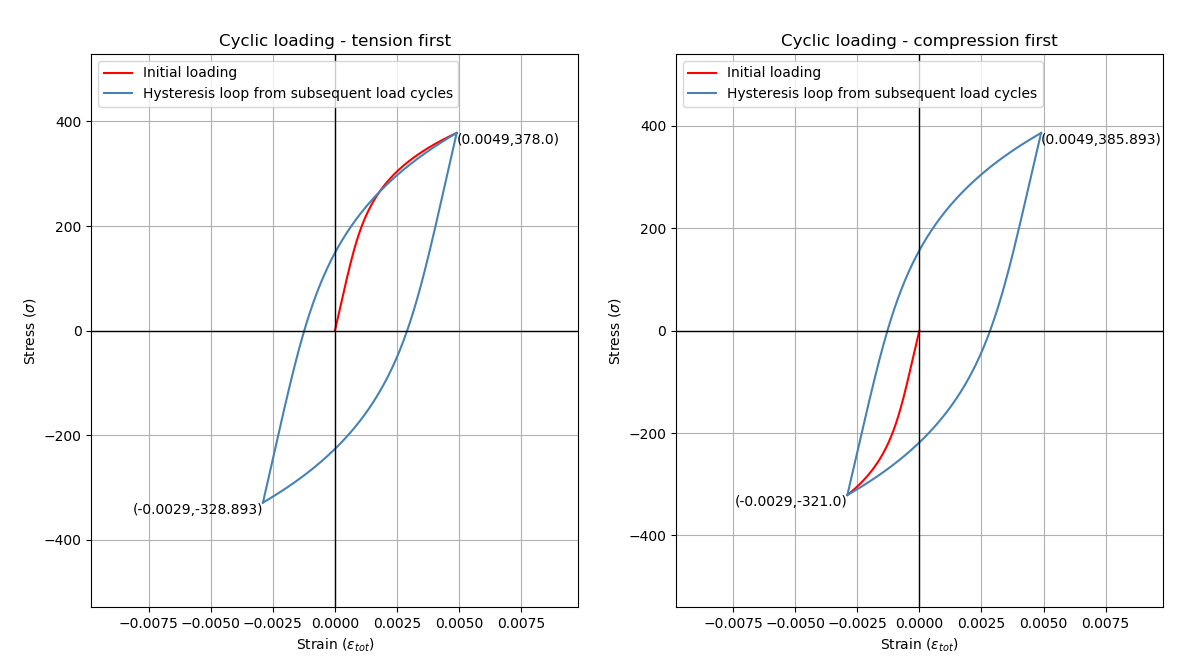

In this example, we will use the stress_strain_diagram to visualise the effects of residual stresses for a material subjected to non-zero mean stress. The material parameters (K and n) are already known so we do not need to obtain them from any data. We specify the max_stress is 378 MPa and the min_stress is -321 MPa. We will do this for two scenarios; initial tensile load, and initial compressive load. Upon inspection of the results we see for the initial tensile load, the min_stress in the material is actually -328.893 MPa which exceeds the min_stress we specified in our test. When we have an initial compressive load, the max_stress is 385.893 MPa which exceeds the max_stress we specified in our test. These results are not an error and are caused by the residual stresses in the material that were formed during the first loading cycle. In the case of an initial tensile load, when the material was pulled apart in tension by an external force, the material pulls back but due to plastic deformation, these internal forces in the material are not entirely removed, such that when the first compressive load peaks, the material’s internal stresses add to the external compressive forces. This phenomenon is important in load sequence effects for variable amplitude fatigue.

from reliability.PoF import stress_strain_diagram

import matplotlib.pyplot as plt

plt.figure()

plt.subplot(121)

print('Tension first')

stress_strain_diagram(E=210000, K = 1200, n = 0.2, max_stress=378,min_stress=-321,initial_load_direction='tension')

plt.title('Cyclic loading - tension first')

plt.subplot(122)

print('\nCompression first')

stress_strain_diagram(E=210000, K = 1200, n = 0.2, max_stress=378,min_stress=-321,initial_load_direction='compression')

plt.title('Cyclic loading - compression first')

plt.gcf().set_size_inches(12,7)

plt.show()

'''

Tension first

Results from stress_strain_diagram:

Max stress: 378.0

Min stress: -328.89311218003513

Max strain: 0.004901364196875

Min strain: -0.0028982508530831477

Compression first

Results from stress_strain_diagram:

Max stress: 385.89311218003513

Min stress: -321.0

Max strain: 0.004901364196875

Min strain: -0.0028982508530831477

'''

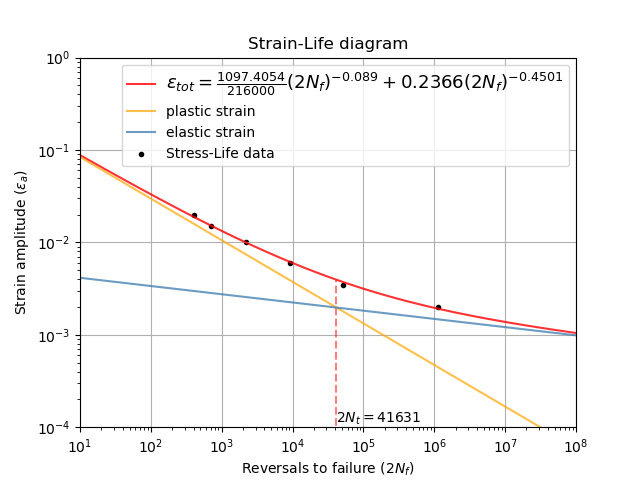

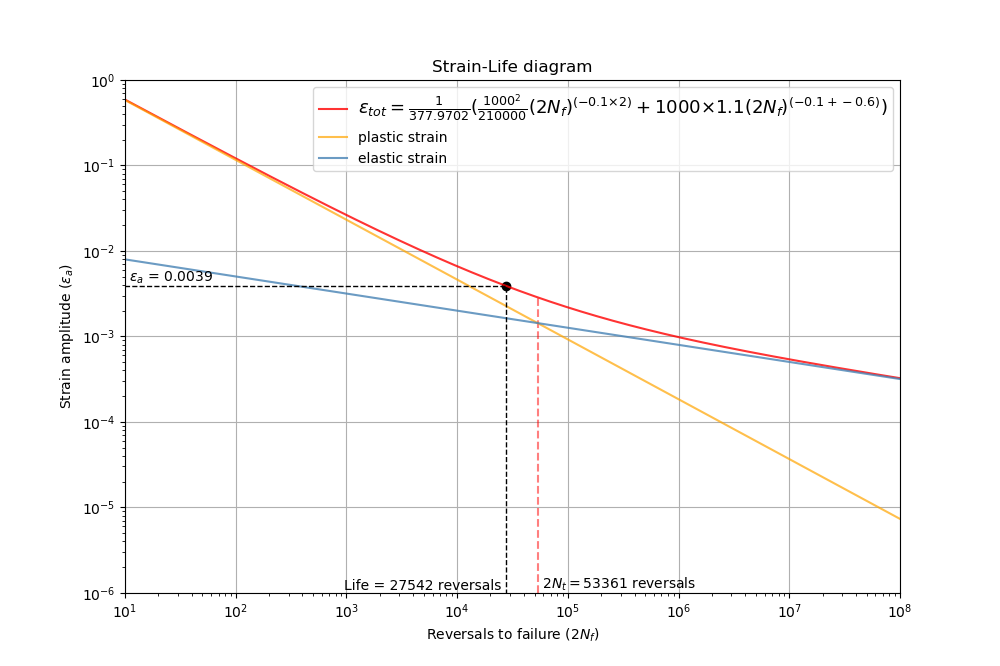

Strain-Life diagram

The function strain_life_diagram provides a visual representation of the Coffin-Manson relationship between strain and life. In this equation, strain is split into elastic strain and plastic strain which are shown on the plot as straight lines (on a log-log scale), and life is represented by reversals (with 2 reversals per cycle). The total strain amplitude is used to determine the fatigue life by solving the Coffin-Manson equation. When a min_stress or min_strain is specified that results in a non-zero mean stress, there are several mean stress correction methods that are available. These are ‘morrow’, ‘modified_morrow’ (also known as Manson-Halford) , and ‘SWT’ (Smith-Watson-Topper). The default method is ‘SWT’ but can be changed using the options described below. The equation used is displayed in the legend of the plot. Also shown on the plot is the life of the material at the specified strain amplitude, and the transition life (2Nt) for which the material failure transitions from being dominated by plastic strain to elastic strain.

Note that if you do not have the parameters sigma_f, epsilon_f, b, c, but you do have stress, strain, and cycles data then you can use the function stress_strain_life_parameters_from_data.

The residual stress in a material subjected to non-zero mean stress (as shown in the previous example) are not considered in this analysis, and the specified max and min values for stress or strain are taken as the true values to which the material is subjected.

API Reference

For inputs and outputs see the API reference.

Example 4

from reliability.PoF import strain_life_diagram

import matplotlib.pyplot as plt

strain_life_diagram(E=210000, sigma_f=1000, epsilon_f=1.1, b = -0.1,c=-0.6, K = 1200, n = 0.2, max_strain=0.0049, min_strain=-0.0029)

plt.show()

'''

Results from strain_life_diagram:

Failure will occur in 13771.39 cycles (27542.78 reversals).

'''

References:

Probabilistic Physics of Failure Approach to Reliability (2017), by M. Modarres, M. Amiri, and C. Jackson. pp. 23-33